Making Plastic Strips: Our Custom Extrusion Process

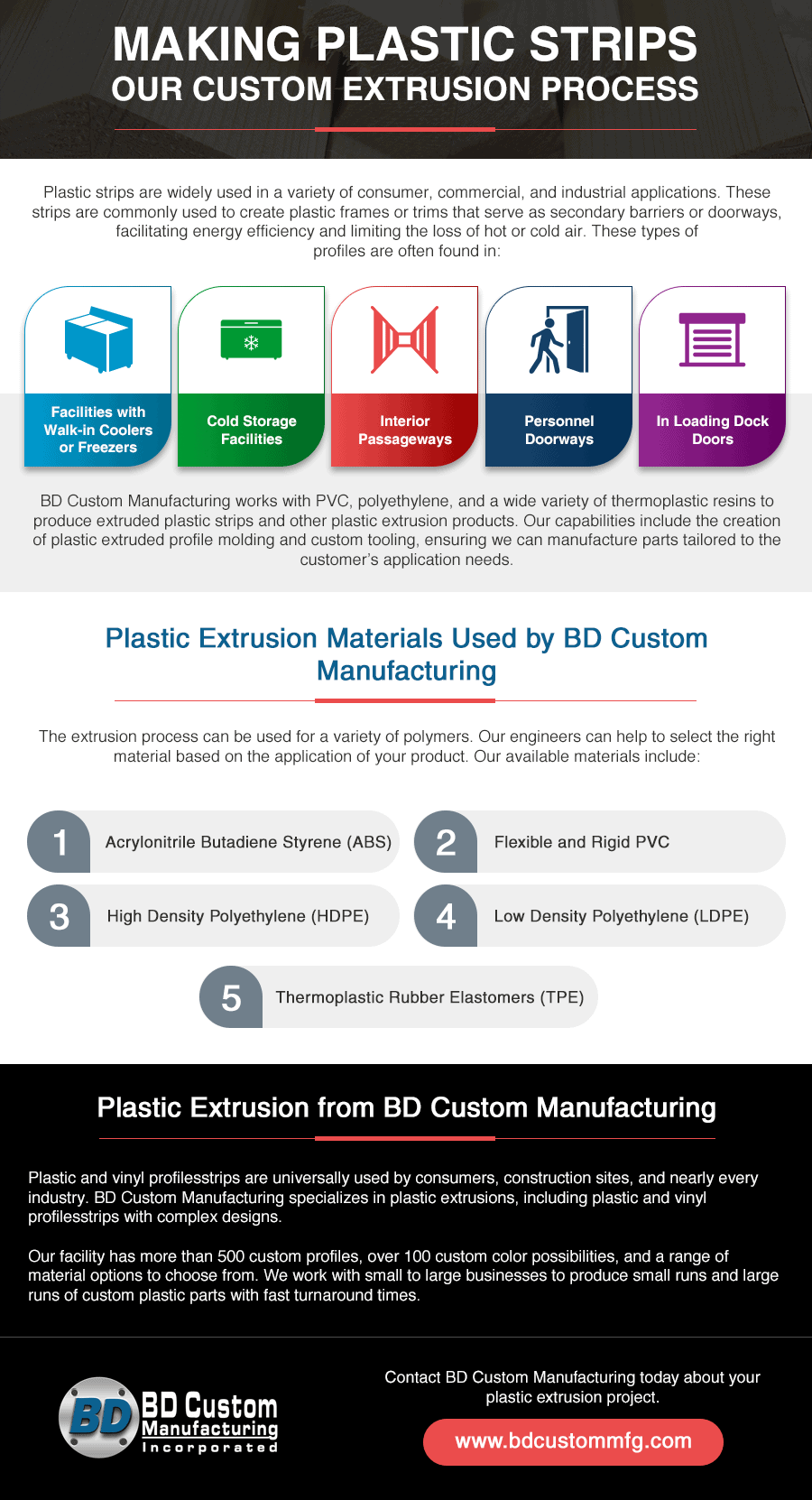

Leave a CommentPlastic strips are widely used in a variety of consumer, commercial, and industrial applications. These strips are commonly used to create plastic frames or trims that serve as secondary barriers or doorways, facilitating energy efficiency and limiting the loss of hot or cold air. These types of profiles are often found in:

- Facilities with walk-in coolers or freezers

- Cold storage facilities

- Interior passageways

- Personnel doorways

- In loading dock doors

BD Custom Manufacturing works with PVC, polyethylene, and a wide variety of thermoplastic resins to produce extruded plastic strips and other plastic extrusion products. Our capabilities include the creation of plastic extruded profile molding and custom tooling, ensuring we can manufacture parts tailored to the customer’s application needs.

The Plastic Strip Extrusion Process

Plastic or vinyl strips need to be flexible, rigid, or both and durable. While the strips themselves may seem simple, the extrusion process used to create them is somewhat complex. The process of creating high-quality vinyl strips and plastic strips may include:

AutoCAD

Computer-Aided Design (CAD) software is nearly universal for creating complex designs across industries. Design engineers use AutoCAD software to create designs, as well as run virtual tests to identify problems and improve those designs before moving into real-world prototyping or testing phases.

AutoCAD is used to create extrusion die templates for profiles, plastic strips, and more. CAD design files can also be converted into instructions used by the Computer Numerical Control (CNC) machinery used to automate many manufacturing processes.

Wire EDM

The dies used in plastic extrusion must hold their complex shape even under high-pressure conditions. Wire Electrical Discharge Machining (EDM) is a reductive machining process that uses electrical discharges to remove material from very hard metals. Electrical force on either side of the die plate breaks down the metal’s dielectric properties and carves through the material at precise points.

This allows manufacturers to realize die designs with complex geometries, even when working with the hard materials used to create dies that will withstand molten materials and tons of force. Manufacturers often use wire EDM to create dies for plastic extrusions.

CNC Machining

CNC machining is the other primary method for creating dies and molds. Computers guide automated lathes, drills, and other tooling to create the intended design. CNC tools are often operated from all three planes to speed up the creation of complex dies, molds, and forms by performing multiple operations simultaneously.

This process requires high-quality tools to ensure that dies and their extruded parts meet customized specifications and tolerances. BD Custom Manufacturing has custom tooling capabilities for custom plastic parts.

Extrusion

Plastic extruders contain one or more large screws, which turn and generate heat. Plastic powders, resin, or pellets are poured into a hopper, which feeds the material into the screw chamber. The screw pushes the plastic into a barrel that is also heated. As the plastic melts from the heat generated by the barrel heaters and the screw, the molten plastic is pushed through a filter screen and into the die.

Up to this point, the process is quite similar to plastic injection molding. The primary difference here is that plastic extrusion is a continuous process flowing through a die which guides the melted plastic into an even flow, while injection molding forms individual parts that must be ejected from the mold.

To create plastic sheets or strips, the extruded plastic is pulled through a series of cooling tanks and or vacume sizers. These provide sufficient cooling and also help determine the final thickness and texture of the strips

Uses of Plastic and Vinyl Strips

Plastic and vinyl strips are used in a variety of industries. They are commonly used as construction materials because of their longevity, customizability, and smooth finish. Some of the most popular plastic and vinyl strip products include:

Construction

- Edging

- Fences

- Weatherstripping

- Window frames

- Tubing

- Post

- Pipe

Industrial

- Tracks

- Electrical wire covers

- Equipment trim and protectors

- Machine trim and protectors

Plastic and vinyl strips are just one type of extrusion product, but they can be customized to create many different products and hold different design tolerances and finishes.

Other Plastic Extrusions and Their Uses

Plastic extrusions can be used to create more than sheets and strips. Extrusion dies can be tooled to hold a variety of precise designs that create thousands of products which are just as universal as plastic strips. BD Custom Manufacturing specializes in plastic extrusions of all types, and our facility has over 500 custom profiles that produce plastic extrusions up to six inches wide. with details as fine as 3/32 of an inch.

Our facility can create a wide variety of products such as:

- Curtain tracks

- Door frames

- Door trims

- Light inserts

- Light tubes

- Tent tracks

- Screw covers

- Window trims

- Slide tracks

BD Custom Manufacturing features plastic trim molding. We produce trim molding with a smooth and durable finish that resists stains and chips. Our plastic profile molding has a variety of end uses, including:

- Wire channels

- Seals

- Door jambs

- Window inserts

- Gaskets

- Ceiling trims

- H moldings

- Data strips

BD Custom Manufacturing also provides custom finishes and attributes. Our facility has more than 100 custom color choices that can be built into the material. Our extrusions can be manufactured with weather-resistant PVC materials for exterior-use products and parts. BD Custom Manufacturing can tool a variety of custom dies to create extrusions of myriad thicknesses and designs.

Plastic Extrusion Materials Used by BD Custom Manufacturing

The extrusion process can be used for a variety of polymers. Our engineers can help to select the right material based on the design and application of your product. Our available materials include:

- Acrylonitrile butadiene styrene (ABS). ABS plastic is lightweight, strong, and resistant to impact and weather damage.

- Flexible and Rigid PVC.PVC extrusions resist corrosion and are FDA approved for use in food and beverage applications. Flexible PVC is soft and bendable throughout the life of the product. We can also produce furniture-grade PVC.

- High Density Polyethylene (HDPE). HDPE and standard polyethylene tubing are non-toxic and resistant to corrosion, abrasion, odors, and stains.

- Low Density Polyethylene (LDPE). LDPE is flexible and shares many of the same beneficial attributes as HDPE.

- This material is light and features a high level of shatter resistance. It can also create clear products.

- Polypropylene resists moisture damage, chemicals, and electricity, making it suitable for indoor or outdoor use.

- Commonly used for consumer products, polystyrene is shatter-resistant and FDA compliant. It also holds color well and has a glossy finish.

- Thermoplastic rubber elastomers (TPE). TPE extrusions are strong, flexible, and resistant to chemical damage.

Plastic Extrusion from BD Custom Manufacturing

Plastic and vinyl profilesstrips are universally used by consumers, construction sites, and nearly every industry. BD Custom Manufacturing specializes in plastic extrusions, including plastic and vinyl profilesstrips with complex designs.

Our facility has more than 500 custom profiles, over 100 custom color possibilities, and a range of material options to choose from. We work with small to large businesses to produce small runs and large runs of custom plastic parts with fast turnaround times.

Contact BD Custom Manufacturing today about your plastic extrusion project.