Whether your profile extrusion is simple, complex or a co-extrusion, BD Custom can design the extrusion tool that best fits your need. Using Auto CAD and wire EDM technology we can design and develop the extrusion tooling that allows us to manufacture your high quality plastic profile. In addition to new tooling, we have much experience in using customer owned tooling. Only minor adaptations are needed on transfer tools to save you time and money when you are seeking a new processor to run your existing tooling.

Custom Tooling and Standard Options

BD offers a full suite of standard tooling options, and we also build client-designed tools on request. Custom tooling allows manufacturers to design the most efficient equipment possible for their needs, and it allows them to create never-before-seen products that will stand out from their competition. With custom tooling, clients can enjoy unparalleled levels of freedom in their manufacturing processes.

BD also can accommodate customer-owned or -designed tooling in our manufacturing processes. We use advanced analytic software to make copies of and improve upon existing tooling as needed, which allows us to seamlessly blend our processes with yours. With BD’s comprehensive range of customization capabilities, we can create a mold to fit whatever tooling designs you supply.

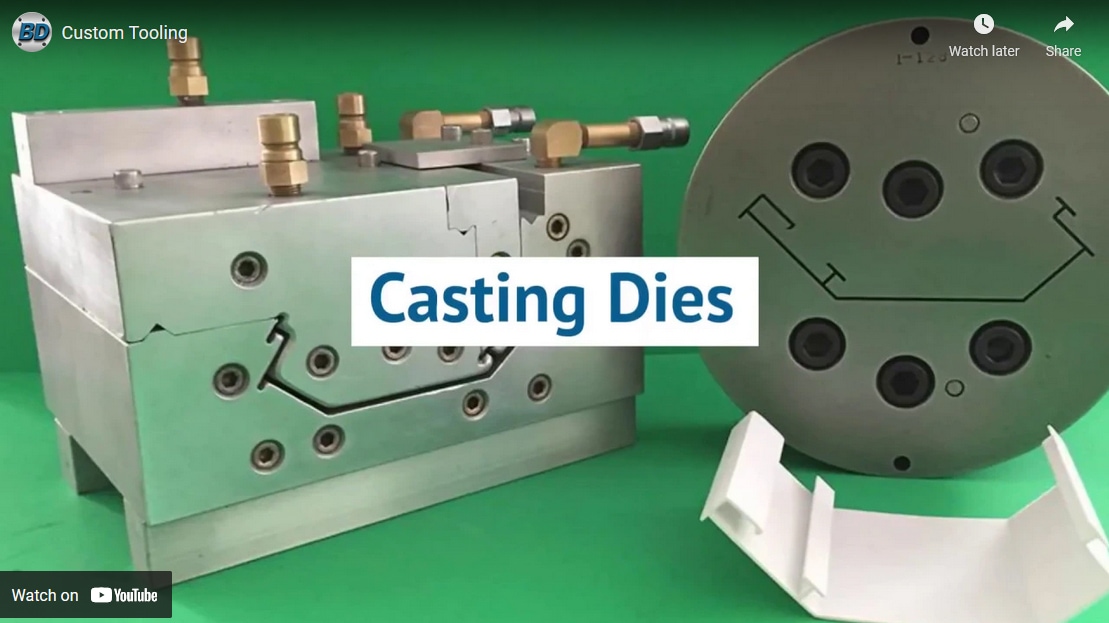

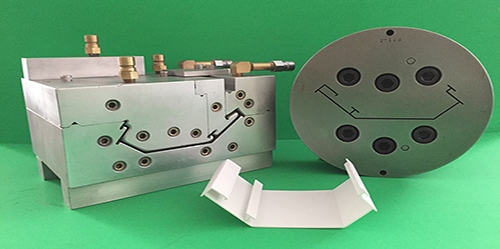

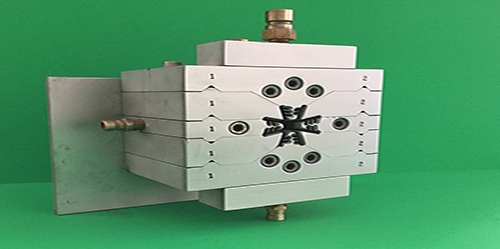

Casting Die Tooling

BD offers a full range of die cast tooling abilities for clients who seek custom parts and components. We work with many grades of steel to develop profile dies that can suit a wide range of applications. If you seek a die that doesn’t match one of the many types we have in stock, we can use CNC processes to efficiently build a die to your specifications.

We also offer a wide array of vacuum sizing services for clients seeking to work with plastic. In this process, we use calibrated vacuum pressure to form consistent plastic parts that conform to the specifications of their corresponding extruded components. We can perform vacuum sizing on many types of plastic, including PVC, polyethylene, and most thermoplastic resins, and we ensure that finished plastic products meet dimensional specifications without thin spots or other imperfections.

Create Your Next Success with BD Custom Manufacturing

BD Custom Manufacturing brings decades of experience to the tooling and die manufacturing fields. If you would like to see how our innovative processes will result in your next industry success, don’t hesitate to contact us or request a quote today.