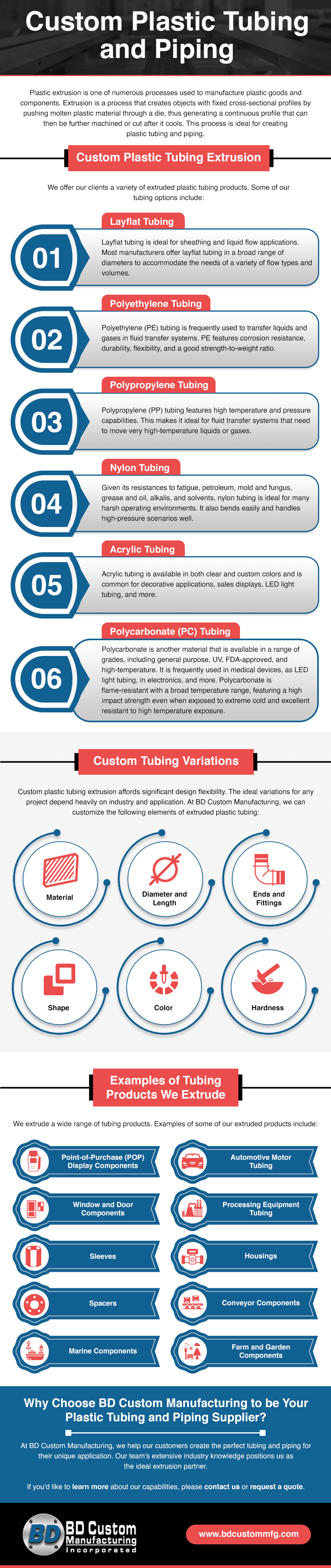

Plastic extrusion is one of numerous processes used to manufacture plastic goods and components. Extrusion is a process that creates objects with fixed cross-sectional profiles by pushing molten plastic material through a die, thus generating a continuous profile that can then be further machined or cut after it cools. This process is ideal for creating plastic tubing and piping.

Custom Plastic Tubing Extrusion

We offer our clients a variety of extruded plastic tubing products. Some of our tubing options include:

Layflat Tubing

Layflat tubing is ideal for sheathing and liquid flow applications. Most manufacturers offer layflat tubing in a broad range of diameters to accommodate the needs of a variety of flow types and volumes.

Polyethylene Tubing

Polyethylene (PE) tubing is frequently used to transfer liquids and gases in fluid transfer systems. PE features corrosion resistance, durability, flexibility, and a good strength-to-weight ratio.

Polypropylene Tubing

Polypropylene (PP) tubing features high temperature and pressure capabilities. This makes it ideal for fluid transfer systems that need to move very high-temperature liquids or gases.

Nylon Tubing

Given its resistances to fatigue, petroleum, mold and fungus, grease and oil, alkalis, and solvents, nylon tubing is ideal for many harsh operating environments. It also bends easily and handles high-pressure scenarios well.

Acrylic Tubing

Acrylic tubing is available in both clear and custom colors and is common for decorative applications, sales displays, LED light tubing, and more.

Polycarbonate (PC) Tubing

Polycarbonate is another material that is available in a range of grades, including general purpose, UV, FDA-approved, and high-temperature. It is frequently used in medical devices, as LED light tubing, in electronics, and more. Polycarbonate is flame-resistant with a broad temperature range, featuring a high impact strength even when exposed to extreme cold and excellent resistant to high temperature exposure.

Custom Tubing Variations

Custom plastic tubing extrusion affords significant design flexibility. The ideal variations for any project depend heavily on industry and application. At BD Custom Manufacturing, we can customize the following elements of extruded plastic tubing:

- Material

- Diameter and length

- Ends and fittings

- Shape

- Color

- Hardness

We can also ensure that custom designs comply with guidelines such as FDA, UL, RoHS, and other regulatory standards. We have extensive experience extruding tubing for a range of projects and our team regularly assists clients in the decision-making process.

Examples of Tubing Products We Extrude

We extrude a wide range of tubing products. Examples of some of our extruded products include:

- Point-of-purchase (POP) display components

- Automotive motor tubing

- Window and door components

- Processing equipment tubing

- Sleeves

- Housings

- Spacers

- Conveyor components

- Marine components

- Farm and garden components

Why Choose BD Custom Manufacturing to be Your Plastic Tubing and Piping Supplier?

At BD Custom Manufacturing, we help our customers create the perfect tubing and piping for their unique application. Our team’s extensive industry knowledge positions us as the ideal extrusion partner.

We specialize in working with small- to midsize plastics customers across industries. We offer:

- Quick turnarounds

- Extensive quality control

- Experienced and capable staff

- Custom tooling design

- Plastic trim molding

- PVC edge trim

- PVC furniture parts

If you’d like to learn more about our capabilities, please contact us or request a quote.