The extrusion process is used to form plastic materials into specific profiles. These extruded profiles may be the product, or the extruded profile may be a component or material for another manufacturing process. Extruded plastic may be solid or hollow depending on the intended application use.

BD Custom Manufacturing has been a leading provider of extruded plastic solutions for small- and medium-sized plastics customers since 1993. We continuously invest in the latest plastic extrusion technology, processes, and experienced personnel to ensure our customers receive the highest-quality parts and the attention they deserve on every project.

The Plastic Extrusion Process Simplified

The plastic extrusion manufacturing process creates two-dimensional shapes from melted, raw plastic material. While specifics may vary based on the unique project, the plastic extrusion process typically follows these five steps:

- Raw plastic in the form of pellets or resin is fed into a hopper/extruder.

- Raw plastic travels to the feed throat and onto a large spinning screw within the horizontal barrel.

- The plastic is heated beyond the melting point of the specific material.

- The molten plastic becomes fully mixed as it travels along the screw, after which it flows across a screen and breaker plate. This step is critical to remove any contaminants or inconsistencies in the plastic.

- The plastic is then forced through a die where it is formed into a continuous profile.

Plastic extrusion is used to produce many items, such as pipes and tubing, molding, custom profiles, and other plastic shapes. After the extrusion process is complete, extruded plastics often undergo various other machining processes to reach their final design specifications, such as cutting, punching, bending, or forming.

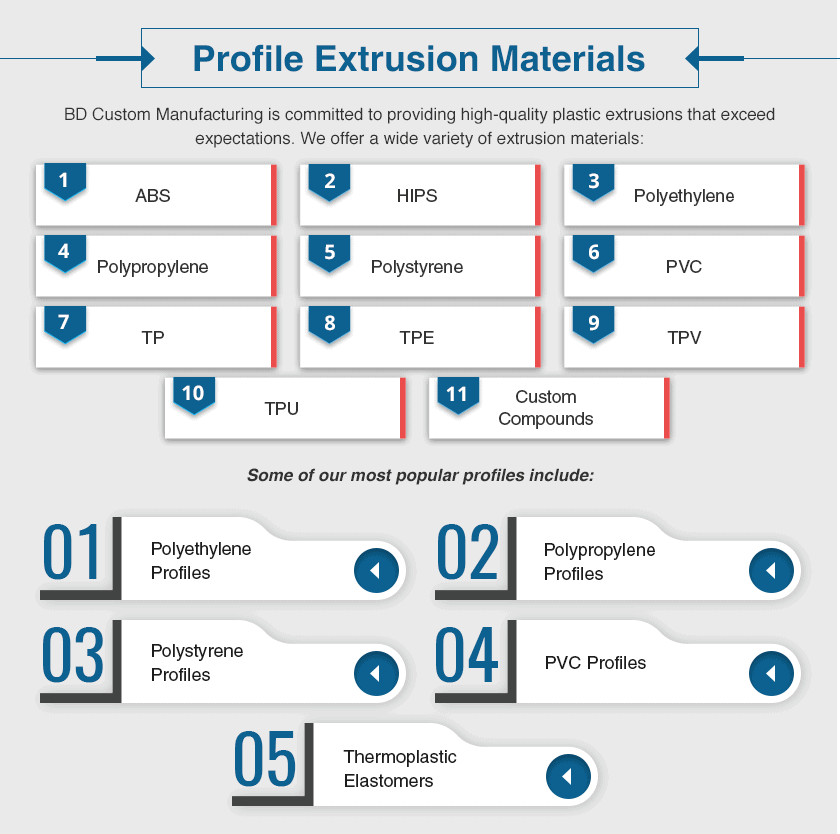

Profile Extrusion Materials

BD Custom Manufacturing is committed to providing high-quality plastic extrusions that exceed expectations. We offer a wide variety of extrusion materials:

- ABS

- HIPS

- Polyethylene

- Polypropylene

- Polystyrene

- PVC

- TP

- TPE

- TPV

- TPU

- Custom compounds

Some of our most popular profiles include:

- Polyethylene profiles feature good flexibility, are lightweight, and are simple to produce.

- Polypropylene profiles are easy to produce, have fair impact strength, and good chemical resistance.

- Polystyrene profiles are affordable, offer outstanding electrical properties, and maintain good dimensional stability, but shouldn’t be used with high temperatures.

- PVC profiles are very cost-effective for general purpose applications, making them one of the most popular non-latex profile materials.

- Thermoplastic elastomers feature high flexibility, absorb vibrations well, and retract to their original form after being elongated.

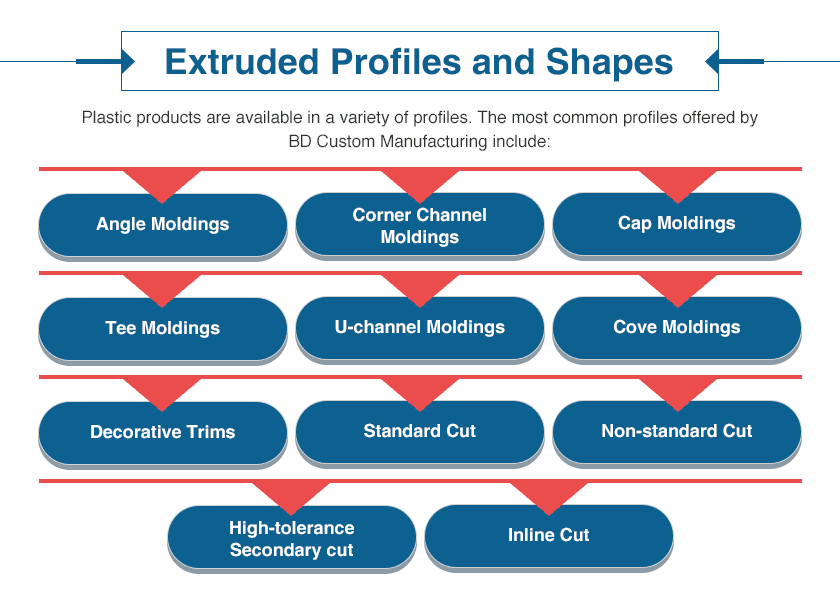

Extruded Profiles and Shapes

Plastic products are available in a variety of profiles. The most common profiles offered by BD Custom Manufacturing include:

- Angle moldings

- Corner channel moldings

- Cap moldings

- Tee moldings

- U-channel moldings

- Cove moldings

- Decorative trims

- Standard cut

- Non-standard cut

- High-tolerance secondary cut

- Inline cut

Extrusion Product Applications

Custom extruded plastic profiles are essential in the creation of a variety of products that serve a broad spectrum of applications and industries. At BD Custom Manufacturing, we commonly create custom extruded plastic shapes for use in:

- Construction

- Lighting

- Marine

- Recreational vehicles

- Refrigeration

- Power management

- Upholstery and furniture

Contact BD Custom Manufacturing Today

BD Custom Manufacturing is an expert in custom plastic profile extrusions, and we specialize in working with small- and medium-sized plastics businesses to meet their needs. We pride ourselves on our superior customer service and attention. Please contact us for more information about our plastic extrusions and other capabilities.