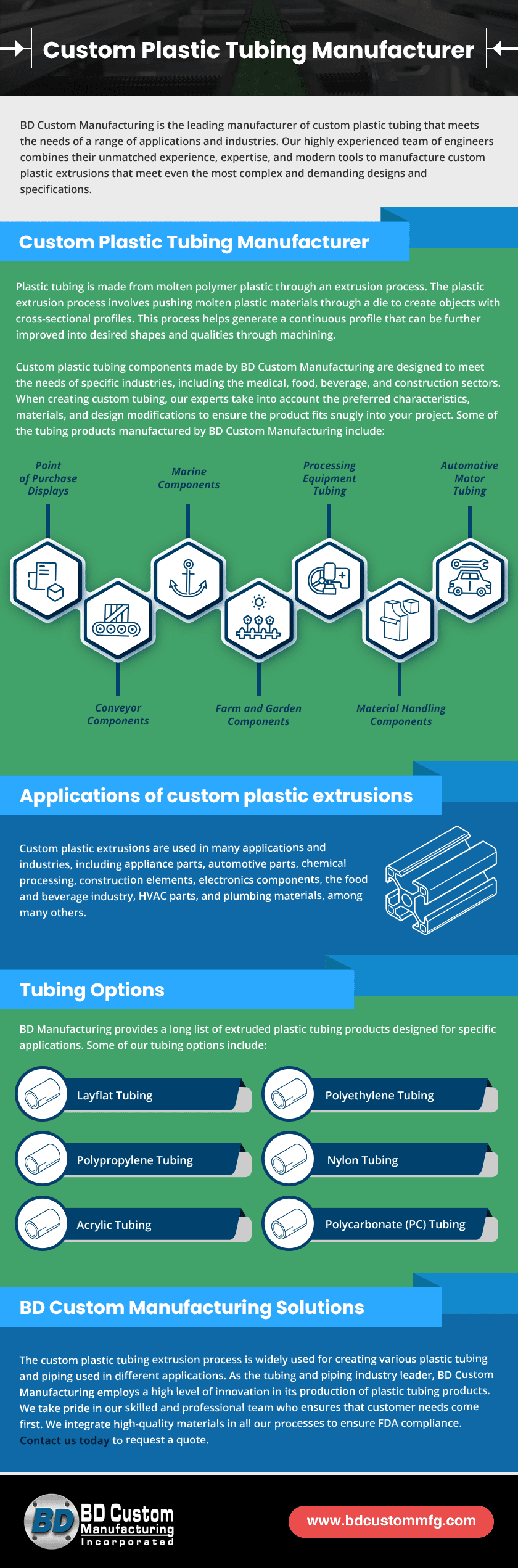

Custom Plastic Tubing Manufacturer

BD Custom Manufacturing is the leading manufacturer of custom plastic tubing that meets the needs of a range of applications and industries. Our highly experienced team of engineers combines their unmatched experience, expertise, and modern tools to manufacture custom plastic extrusions that meet even the most complex and demanding designs and specifications.

Custom Plastic Tubing Manufacturer

Plastic tubing is made from molten polymer plastic through an extrusion process. The plastic extrusion process involves pushing molten plastic materials through a die to create objects with cross-sectional profiles. This process helps generate a continuous profile that can be further improved into desired shapes and qualities through machining.

Custom plastic tubing components made by BD Custom Manufacturing are designed to meet the needs of specific industries, including the medical, food, beverage, and construction sectors. When creating custom tubing, our experts take into account the preferred characteristics, materials, and design modifications to ensure the product fits snugly into your project. Some of the tubing products manufactured by BD Custom Manufacturing include:

- Point of purchase displays

- Marine components

- Processing equipment tubing

- Automotive motor tubing

- Conveyor components

- Farm and garden components

- Material handling components

Applications of custom plastic extrusions

Custom plastic extrusions are used in many applications and industries, including appliance parts, automotive parts, chemical processing, construction elements, electronics components, the food and beverage industry, HVAC parts, and plumbing materials, among many others.

Tubing Options

BD Manufacturing provides a long list of extruded plastic tubing products designed for specific applications. Some of our tubing options include:

Layflat Tubing: Layflat tubing is preferred for sheathing and liquid flow applications. We understand no two applications are the same, which is why we offer layflat tubing in a wide range of diameters to handle the needs of various flow volumes.

Polyethylene Tubing: Polyethylene tubing is the most preferred tubing for the transfer of liquids and gases in typical fluid transfer applications. This tubing type boasts many features, including high resistance to corrosion, unmatched durability, and flexibility. It also offers a higher strength-to-weight ratio, making it ideal for demanding and rigorous applications.

Polypropylene Tubing: Polypropylene Tubing comes with exceptional temperature and pressure resistance that is rare in other products of the same category. Additionally, this tubing is acclaimed for its durability, low corrosiveness, low friction, and resistance to high temperatures. Ideally, polypropylene tubing is suitable for fluid transfer systems designed to move high-temperature gases and liquids.

Nylon Tubing: Nylon tubing is preferred for harsh operating environments thanks to its high resistance to petroleum, fungus, alkalis, and chemicals. This type of tubing bends easily to handle high-pressure applications well. Other benefits of nylon tubing include high and low-temperature resistance and high resistance to abrasions that help prevent accidental damage, which could have the potential to cause leaks or spills.

Acrylic Tubing: Acrylic features excellent optical clarity and transparency. Acrylic tubing also boasts a high resistance to temperature variations and offers up to 17 times the impact resistance of ordinary glass. It is also highly resistant to various chemicals. We provide a range of acrylic tubing products with clear and custom colors ideal for decorations, sales displays, and LED light tubing for cars.

Polycarbonate (PC) Tubing: Polycarbonate tubing is available in different grades, including and not limited to: general purpose, UV, FDA-approved, and high-pressure options. This tubing features high flame resistance, high impact strength, and unmatched resistance to extreme temperature exposures. Polycarbonate tubing is ideal for numerous applications, including medical devices, LED light tubes, and electronics.

BD Custom Manufacturing Solutions

The custom plastic tubing extrusion process is widely used for creating various plastic tubing and piping used in different applications. As the tubing and piping industry leader, BD Custom Manufacturing employs a high level of innovation in its production of plastic tubing products. We take pride in our skilled and professional team who ensures that customer needs come first. We integrate high-quality materials in all our processes to ensure FDA compliance. Contact us today to request a quote.