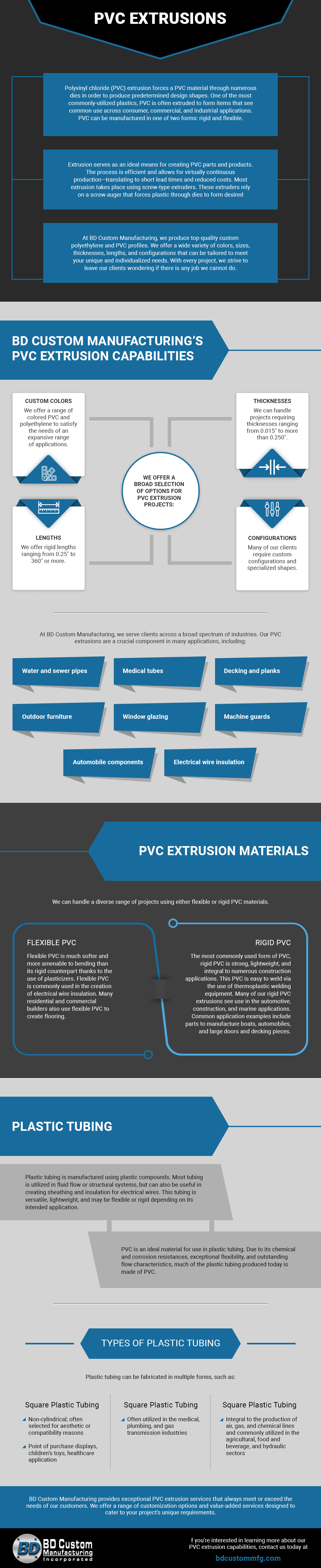

Polyvinyl chloride (PVC) extrusion forces a PVC material through numerous dies in order to produce predetermined design shapes. One of the most commonly-utilized plastics, PVC is often extruded to form items that see common use across consumer, commercial, and industrial applications. PVC can be manufactured in one of two forms: rigid and flexible.

Extrusion serves as an ideal means for creating PVC parts and products. The process is efficient and allows for virtually continuous production—translating to short lead times and reduced costs. Most extrusion takes place using screw-type extruders. These extruders rely on a screw auger that forces plastic through dies to form desired shapes.

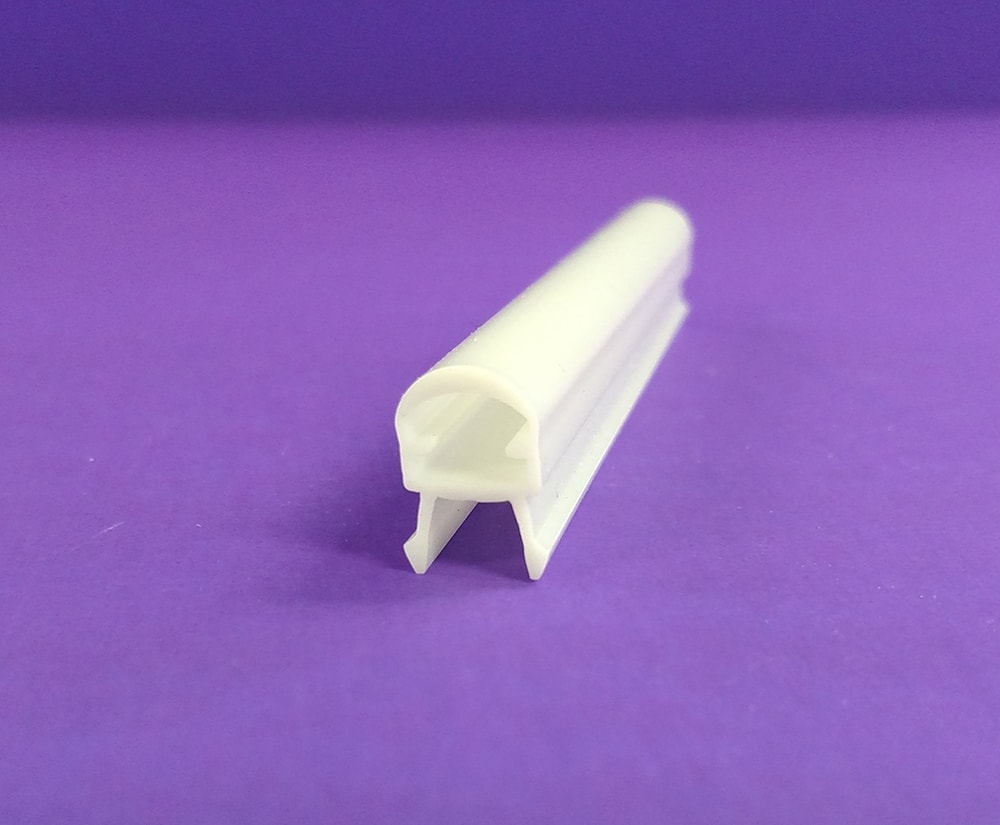

At BD Custom Manufacturing, we produce top-quality custom polyethylene and PVC profiles. We offer a wide variety of colors, sizes, thicknesses, lengths, and configurations that can be tailored to meet your unique and individualized needs. With every project, we strive to leave our clients wondering if there is any job we cannot do.

BD Custom Manufacturing’s PVC Extrusion Capabilities

We offer a broad selection of options for PVC extrusion projects:

- Custom colors. We offer a range of colored PVC and polyethylene to satisfy the needs of an expansive range of applications.

- Thicknesses. We can handle projects requiring thicknesses ranging from 0.015″ to more than 0.250″.

- Lengths. We offer rigid lengths ranging from 0.25″ to 360″ or more.

- Configurations. Many of our clients require custom configurations and specialized shapes.

At BD Custom Manufacturing, we serve clients across a broad spectrum of industries. Our PVC extrusions are a crucial component in many applications, including:

- Water and sewer pipes

- Medical tubes

- Decking and planks

- Outdoor furniture

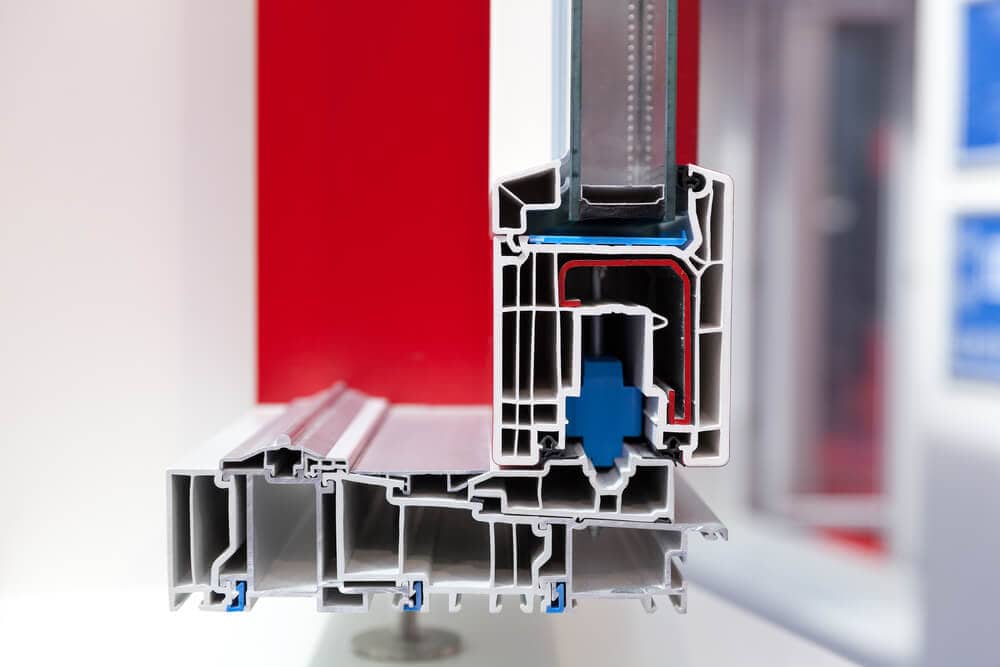

- Window glazing

- Machine guards

- Automobile components

- Electrical wire insulation

PVC Extrusion Materials

We can handle a diverse range of projects using either flexible or rigid PVC materials.

Flexible PVC

Flexible PVC is much softer and more amenable to bending than its rigid counterpart thanks to the use of plasticizers. Flexible PVC is commonly used in the creation of electrical wire insulation. Many residential and commercial builders also use flexible PVC to create flooring.

Rigid PVC

The most commonly used form of PVC, rigid PVC is strong, lightweight, and integral to numerous construction applications. This PVC is easy to weld via the use of thermoplastic welding equipment. Many of our rigid PVC extrusions see use in the automotive, construction, and marine applications. Common application examples include parts to manufacture boats, automobiles, and large doors and decking pieces.

Plastic Tubing

Plastic tubing is manufactured using plastic compounds. Most tubing is utilized in fluid flow or structural systems, but can also be useful in creating sheathing and insulation for electrical wires. This tubing is versatile, lightweight, and may be flexible or rigid depending on its intended application.

PVC is an ideal material for use in plastic tubing. Due to its chemical and corrosion resistances, exceptional flexibility, and outstanding flow characteristics, much of the plastic tubing produced today is made of PVC.

Types of Plastic Tubing

- Plastic tubing can be fabricated in multiple forms, such as:

Square Plastic Tubing

- Non-cylindrical; often selected for aesthetic or compatibility reasons

- Point of purchase displays, children’s toys, healthcare application

Flexible Plastic Tubing

- Integral to the production of air, gas, and chemical lines and commonly utilized in the agricultural, food and beverage, and hydraulic sectors

PVC Extrusion Services from BD Custom Manufacturing

BD Custom Manufacturing provides exceptional PVC extrusion services that always meet or exceed the needs of our customers. We offer a range of customization options and value-added services designed to cater to your project’s unique requirements.

If you’re interested in learning more about our PVC extrusion capabilities, contact us today for additional details or request a quote.

100 Custom Colors

500 Custom Profiles

317,000 Feet of Plastic Per Day

10 Materials Used